In Business Since | License #

In Business Since | License #

What comes to mind when you hear the word "insulation?" Most of us think of fiberglass batts, visualizing pink spun glass fibers that look a lot like cotton candy. Other folks might envision shredded newspaper, the main ingredient in cellulose insulation. Rigid foam boards also belong in this category of diverse, different-looking materials that all aim to save energy in the home by slowing heat transfer.

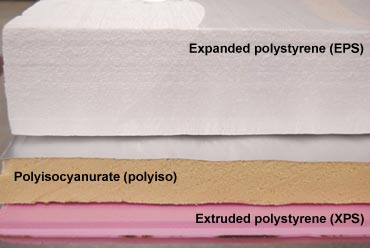

Polyisocyanurate, Extruded polystyrene, and Expanded

polystyrene rigid insulation boards have certain advantages

and limitations.

There are different types of rigid foam insulation, which we'll get to in a minute. But all rigid foam insulation has certain advantages and limitations. Fiberglass and cellulose insulation can't stop air movement, but rigid foam can.

To be an effective air barrier, rigid foam needs to be sealed at joints and edges, but this is fairly easy to accomplish with tape and spray foam. Rigid foam panels come in a variety of thicknesses and widths. 2-ft. x 8-ft. and 4-ft. x 8-ft. panels are most common. Rigid foam cuts easily with a knife or saw. It's typically cut to fit and wedged (friction-fit) into place, but it can also be glued to surfaces with caulk, panel adhesive or spray foam.

Unlike batt and blown insulation, it won't blow or shift out of place once it's installed. Dr. Energy Saver can perform a professional installation of this proven insulation. Contact your local dealer for a free estimate!

On a cost-per-R-value basis, rigid foam is more expensive than fiberglass or cellulose, and it's definitely more difficult to install around obstacles or in odd-shaped spaces. Here are the three main types of rigid foam insulation:

With a comprehensive Home Energy Audit, Dr Energy Saver can help you identify if rigid board insulation is right for your home, and what R-value you need to optimize your savings on your heating and cooling bills.

Looking for a price? Get a no cost, no obligation free estimate.